our products

Applications

VpCI® films are used for many applications including shipping, storage, and work-in-progress (WIP) corrosion protection for metal parts and other components. VpCI® films are available in a variety of sizes and styles depending on the needs of the application. Multifunctional Vapor phase Corrosion Inhibitors (VpCI ), recommended for all packaging needs. Films range from general use polyethylene film to shrink wrap, stretchable, or reinforced constructions.

Applications

VpCI® emitters are used to protect metal from

corrosion in enclosed spaces. This can range from

shipping and storage of parts to protection of

installed components and electronics in enclosed

spaces. VpCI®-130 series foam and BioPad are

available in custom sizes for protection from small to

large volumes. VpCI®-308 pouch is recommended for

larger volumes.

Recommended for packaged and stored electrical

equipment’s.

Applications

Rust preventatives require a clean surface in order to

function to their full effectiveness. Cleaners are used to

remove oils, greases, dirt, and other contamination that

can interfere with rust preventatives. Rust removers can

be used to clean and prepare rusted surfaces for further

protection and should always be followed with a cleaning

and rinsing step using a VpCI®-41x series cleaner.

An organic and biodegradable base chemicals that

remove oxide and tarnish from many metals. These

formulations replace harsh acids.

Non-toxic, and non-flammable use for many applications

Applications

Rust preventatives offer a wide variety of options for

corrosion protection in many different environments and

applications. Products may be categorized by their product

type (oil-based, solvent-based, or water-based), their film

type (thin and dry, oily, or thick), and by their

recommended protection environment (indoors – storage

and shipping, harsh indoor or sheltered outdoor, or

outdoors and other harsh environments). All products may

be applied via brush, spray, or dip methods.

Applications

All coatings deliver exceptional protection against

humidity, saltwater, and oxidizing atmospheres,

even in extreme corrosive outdoor industrial,

marine, or tropical environments. Cortec® offers

a broad range of high-quality, innovative,

environmentally safe coatings. Choosing the

correct products type of protection needed for

short or long term, metal to protect, exposure

“indoor or outdoor”. All products may be applied

via spray, dip or brush.

Applications

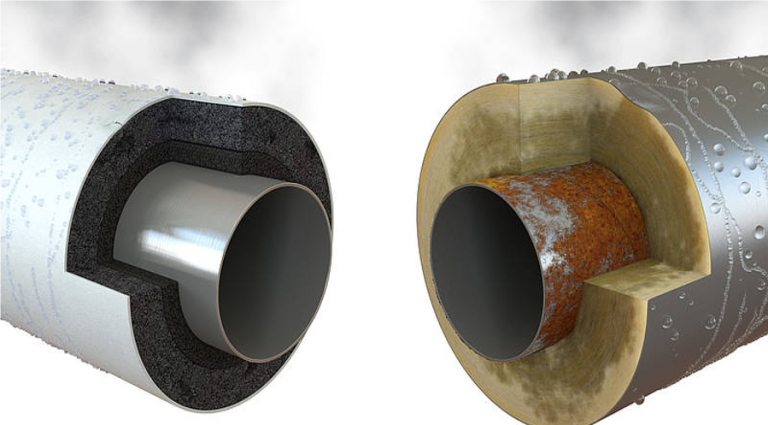

CUI inhibitor provides long-lasting benefits such as

decreased maintenance cost, reduced downtime for

repair and replacement and overall increase safety by

preventing catastrophic failures related to corrosion.

Vapor phase Corrosion Inhibitors in the products enable

CorroLogic® CUI inhibitor to be injected into new or

existing insulation on pipes allowing to migrate through

the insulation to protect metal surfaces below, protects

in wet and dry cycles, and long lasting.

STOPAQ is at heart a Polyisobutene (PIB) based coating, mimicking the natural behaviour of tree sap, with self-healing properties. The coating forms an impervious layer to oxygen, water and MIC, protecting corroding materials such as steel. This leads to permanent adhesion to the surface, extended lifetime of the coating and asset protection.

STOPAQ has superior adhesion to various surface, dry or wet, with minimum preparation requirements. Without the need for primers or specialty tools, our systems are simple and easy to apply.